Filter by Catalogue:

Products Found:

LOOKING FOR SOMETHING?

Green Future Dakota

OUR CIRCULAR ECONOMY

A circular economy is restorative and regenerative by design. This means materials constantly flow around a 'closed loop' system, rather than being used once and then discarded. In the case of plastic, this means simultaneously keeping the value of plastics in the economy, without leakage into the natural environment. This model extends the life cycle of our products while helping minimize waste and generating additional value.

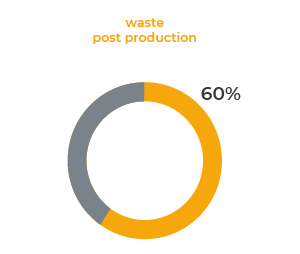

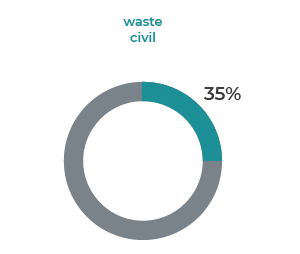

Dakota firmly believes in sustainable building practices. We are committed to the development of our circular economy while also carry out production processes using industrial and consumer waste - with no compromise to quality.

A Sustainable World

Dakota Group is a part of "A Sustainable World" since 2022, the main organization representing sustainable manufacturing and service companies in Italy.

It welcomes small, medium, and large companies that share the idea of sustainable development as "development which allows the present generation to satisfy their needs without compromising the possibility of future generations to satisfy theirs".

"A Sustainable World" is an Italian non-profit organization that represents sustainable companies, supporting the 2030 Agenda for Sustainable Development and the UN Sustainable Development Goals (SDGs). The organization brings together companies of all sizes that share the common goal of sustainable development.

The vision of "A Sustainable World" is to have a sustainable world for us and for others. Its mission is to help drive sustainable business as an engine of economic, social, and civil growth for a more eco-sustainable world.

The association promotes the green economy as a fundamental pillar of the transition to an economic model based on sustainability. It stimulates and helps the transformation of companies and public institutions towards sustainable development, promoting scientific research, innovation, and the development of effective management practices and procedures on a national scale.

"A Sustainable World" promotes the Italian climate agenda, supports and encourages our country in the development of the circular economy and organizes the States General of Sustainability. Furthermore, it awards a prize to companies that have distinguished themselves in the use of innovative activities and processes as well as in relevant national and international sustainability paths.

The added value of "A Sustainable World" is the network of sustainable companies that operates in Italy and abroad. The association strategically helps companies in their transition towards sustainability, through projects that help meet the requirements of the SDGs.

Recycling: part of a larger circle

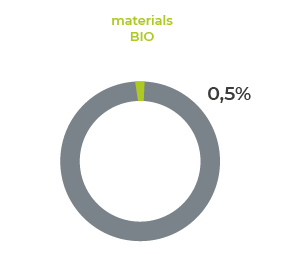

Dakota is committed to reducing its use of virgin plastics, pulling away from a traditional production model, and introducing innovative techniques and uses of recycled materials higher upstream in its production chains.

These regenerated materials mainly come from industrial waste products and, increasingly, from post-consumer plastics.

Is it thus important to note that a circular economy for plastics expands beyond recycling. Dakota Group has been devising and implementing a series of strategic changes to reduce the use of plastics in the past years. These changes occur at every stage of production, starting at product design and ending at packaging and deliveries.

To date, Dakota produces its products using the following types of plastic polymers:

INVESTING IN INNOVATION

SINCE 1980

The start of DakotaIt was only in 1980 when the first plastic presses were put into operation for the molding of construction products. Today, over forty years later, the Dakota Group remains committed to innovating within the construction industry. We consistently expand our product range and innovate on our production technologies - making our products increasingly advanced, performant, and occasionally unique.

Innovate to evolve. The only way forward.

DAKOTA, AT YOUR SERVICE

Contact us for a consulation with one of our specialists or request information about our products and services.

-

Complete the form to write us a message

-

Schedule a call